Sub -Sea System

IOC Paradip Single Point Mooring System (SPM)

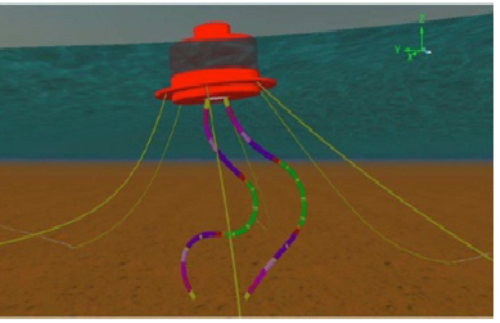

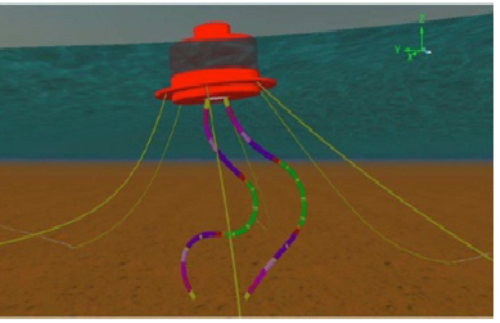

In this project, Aryatech modelled Paradip SPM system with CALM (Catenary Anchor Leg Mooring) arrangement in OrcaFlex. Model was matched with the SBM as closely as possible and then extreme response of the system under various load cases on the submarine hoses, the floating hoses and the mooring hawsers was assessed. The results of the operating conditions were compared with the reports provided by SBM. The work was completed and suggestions were made for improvements to the system based on the investigation and identification of the causes of failures of the subsea hoses and mooring hawser.

SPM for HMEL Mundra Port

Aryatech carried out independent Sub Sea hose analysis of the Mundra SPM. Failure of the recently installed Sub Sea hoses had occurred. The work was completed and solution for installation of new Sub Sea hoses provided to the owners. OrcaFlex was used for this project.

Mooring System for SESA GOA

Aryatech performed design analysis of four sets /configuration of mooring buoy system to include the anchors, buoys, chain, connective jewellery and hawsers at SESA, Goa. Detailed analysis was carried out meeting the requirements of standards set by ABS Rules for Building and Classing Single Point Mooring. OrcaFlex software was used for the task.

Single Point Mooring Verification for ESSAR at Vadinar

Independent Sub Sea hose analysis of the ESSAR Single Point Mooring system was carried out by Aryatech. System was installed at Vadinar to transfer fluids of different density using the Subsea hoses configuration. OrcaFlex software was used to complete the task.

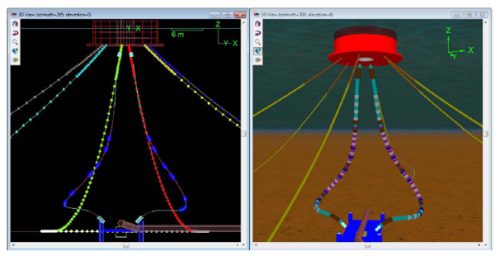

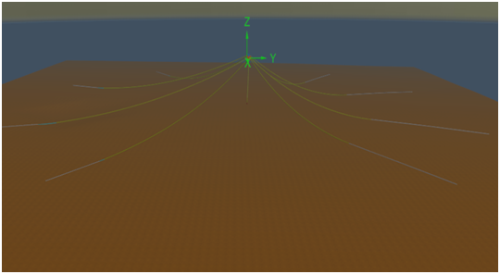

Riser & Mooring Analysis of Drillship Sagar Vijay/ Sagar Bhushan - ONGC

Aryatech is expert in the analysis of Riser and Mooring system using industry standard software packages such as OrcaFlex software. We have completed Riser and Mooring analysis for ONGC drillship at water depth of 265m along the Eastern Coast of India. Scope of the work included checking the feasibility of existing riser capability of ONGC for the said location and designing a feasible mooring configuration. A workable mooring pattern was designed considering the environmental loads and the operational constraints of the drillship. Damaged mooring analysis was performed to check for the critical cases when one or more mooring lines are broken. Analysis was done following the global standards such as API RP 16Q and API RP 2SK.

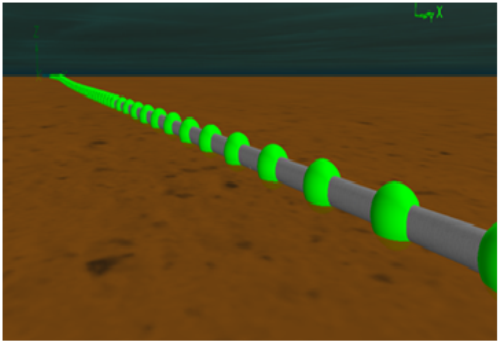

Riser & Pipeline Installation for Union Dredgers

In this project, Aryatech re- modelled 690 m existing subsea pipeline sections to satisfy the new installation methodology acquired by the client and carried out the installation analysis, abandonment & recovery analysis using OrcaFlex to sustain the environmental conditions for the location Halul Island, Qatar. Aryatech provided complete modelling assistance and engineering solution for the pipeline replacement.

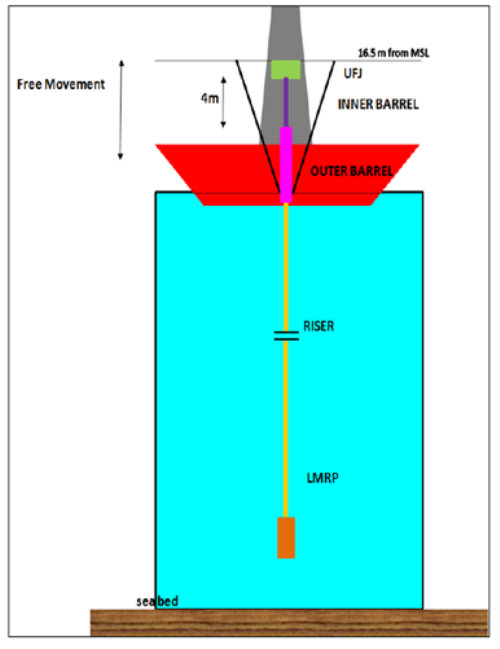

Riser Analysis for Drillship ABAN Abraham

Aryatech carried out Riser analysis for ABAN Offshore Drillship at water depth of 625m and 1500m using OrcaFlex Software. Analysis was performed following the global standards such as API RP 16Q. The primary objective of the project was to design riser make-up for water depth of 625m near eastern coast of India and analysing it for the location specific environment conditions and check for increase in the sea current. Scope of the work also included checking the feasibility of existing riser capability of the drill ship for the said location. A workable Riser Stack up was designed considering the environmental loads and the operational constraints of the drillship.

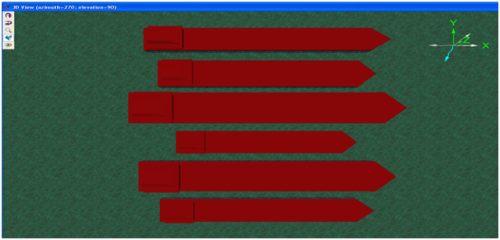

Mooring analysis of a Semisubmersible in the Eastern Coast of India for L & T

Mooring analysis was carried out for a 60X60 semisubmersible with 8 point mooring system. The mooring analysis was carried out as per API RP 2SK. Detailed scope of work included

- Designing and optimizing mooring system for the desalination plant

- Deciding anchors for the system

- Defining Limiting sea states

- Global analysis for operating and survival environment conditions

- Damage analysis- cases if one or more chain breaks

The following parameters were checked for

- Mooring chain loads

- Anchor loads

- Drifting of the moored vessel

- Drift circle definition